News

Water-based wood coatings: what are one-component and two-component systems, and how do you choose between them?

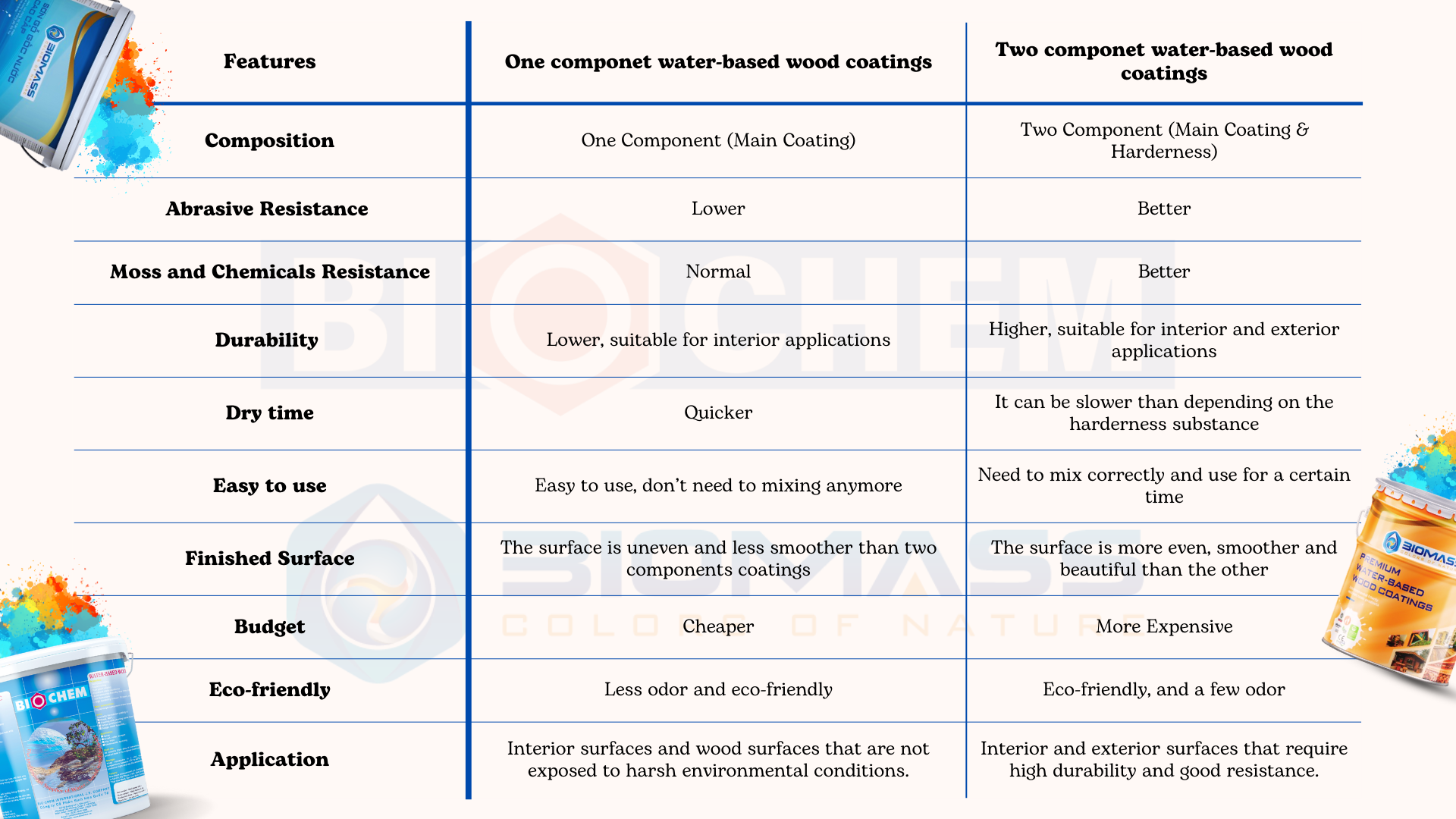

Water-based wood coatings are considered by experts to have a fast growth rate. They are gradually dominating the market and replacing traditional coatings. According to Arizton‘s report on this market, total revenue could reach up to $105 billion by 2026, with a compound annual growth rate (CAGR) of approximately 5% (2021-2026). They are favored for being environmentally friendly, low in odor, and safe for health. Water-based wood coatings come in many varieties, just like the commonly used PU wood coatings. They are mainly divided into two types: one-component and two-component systems. So how can we distinguish between them? And which one should we choose

I/ One-component water-based wood coatings: Fast, convenient, and easy to store

One-component water-based wood coatings are considered easy to use, especially for home projects. They are typically pre-mixed and ready to use without the need for additional mixing. Like other water-based wood coatings, they use water as the solvent. Importantly, they don’t require the addition of a hardener, which extends their shelf life. The biggest advantage of water-based coatings is their ease of use. They are also easy to clean and save time. One-component water-based coatings dry faster than other types and have a lower consumption rate, making them more cost-effective.

1. Durability Of One-component Water-Based Wood Coatings

2. Applications

- Suitable for both interior and exterior wood surfaces.

- Ideal for projects that require environmental protection or high health safety standards. Examples include children’s toys or public facilities such as hospitals and schools.

3. Notice:

Surface Preparation: Wood surface should be clean and dry before spraying

Spraying more layers: Spraying more layers for having the best coverage for wood furniture

Storage: Keep the paint can tightly sealed and store it in a dry place

II/ Two components water-based wood coatings- Durable and beautiful with exceptional coverage

Two-component water-based wood coatings, despite requiring mixing in specific ratios, offer superior coverage, durability, and a more robust finish. These coatings can be considered premium water-based options with many advanced features. The biggest difference compared to one-component coatings is that they require an additional hardener mixed according to the manufacturers specifications. This results in consistent coverage and better wood protection. They are resistant to abrasion and scratches. However, the mixed solution generally has a shorter working time, as it tends to harden more quickly.

Outstanding Characteristic:

- High durability: Provides greater durability and resistance to abrasion and impact, making it ideal for wood surfaces that require long-term protection.

- Moisture and chemical resistance: Superior to one-component water-based coatings, making it suitable for environments with high humidity or chemical exposure.

- Fast drying: Can dry quickly and harden after being properly mixed and applied.

- Beautiful finish: Delivers a smooth and high-quality surface finish

Applications:

- Interior and Exterior Wood: Especially for surfaces that require high protection and durability, such as furniture, wooden doors, wooden floors, and outdoor wood products.

- High-demand projects: Used in projects that require high-quality paint and environmental resistance.

Notice when using two-componets wood coatings

- Correct mixing ratio: Ensure accurate mixing according to the manufacturer’s recommended ratio for optimal results.

- Use promptly: Once mixed, the paint must be used within a specific time before the mixture begins to harden.

- Surface preparation: The wood surface must be thoroughly prepared and cleaned before painting. The surface should be sanded and dusted carefully during preparation and between coats to achieve the best adhesion.

Conclusion and Advise

Contact Us

Biochem International Joint Stock Company

Address : 66, Street No 1, Block 1, Tan Phong Ward, District 7, HCM city.

Tel: (+84-28) 3620 4207 / 3620 4208

Fax: (+84-28) 3620 4206

Website: www.biochem.vn

Email: contacts@biochem.vn

Reference

Arizton: Waterborne Coating Market Report

Tiếng Việt

Tiếng Việt 简体中文

简体中文